3D printing technology has revolutionized various industries, from manufacturing to healthcare, by enabling the creation of complex and customized objects with relative ease. As the market for 3D printers continues to expand, selecting the right printer can be daunting. This guide aims to provide an in-depth overview of some of the best 3D printers available, focusing on different user needs, from hobbyists to professionals.

Top Picks

- Resume Printing Function: Ender 3 has the ability to resume printing even after a power outage or lapse occurs.

- Easy and Qucik Assembly: It comes with several assembled parts, you only need about 2 hours to assemble 20 nuts well.

- Advanced Extruder Technology: Upgraded extruder greatly reduces plugging risk and bad extrustion; V-shape with POM wheels make it move noiseless, smoothly and durable.

- Safety Protected Power Supply: Only needs 5 minutes for hot bed to reach 100 degree.

- Strict Test: Strict testing for key components before delivery and life-time technical supports available.

- 【Overview of Neptune 3 Pro】225x225x280mm/8.85x8.85x11 inch market mainstream printing size can meet the needs of most users. With an STM32 motherboard, all axes of ELEGOO Neptune 3 Pro are driven by silent stepper motors for quieter and more precise movement during printing, which reduces the noise as low as 47-48dB. The easy-to-setup printer comes with the main components pre-assembled, as well as a complete tool kit for quick installation.

- 【Dual-Gear Direct Extruder】The new dual-gear direct drive extruder is made of SUS303 high-quality stainless steel with a 3:1 reduction ratio and stronger extrusion force for smoother filament feeding and more stable & accurate printing, which greatly reduces nozzle clogging and under-extrusion issues, printing effect is better than Bowden extruder. Compatible with multiple filaments such as PLA, TPU, PETG, and ABS.

- 【Nozzle Kit for Better Printing Effect】The nozzle kit contains a TC4 titanium alloy throat pipe, an aluminum alloy flat heat sink structure, and a brass nozzle.The widened aluminum heat sink paired with the front close-fitting efficient cooling fan for a better heat dissipation effect and lower the temperature of the throat pipe, thereby reducing the possibility of nozzle clogging.

- 【Smarter Printing Experience】Auto mesh bed leveling adopts a non-contact high precision sensor to automatically scan 36 (6x6) points of the hotbed and collect data in real-time, and then adjust the Z-axis height to compensate for any irregularities and unevenness of the printing platform. (Only applicable to metal printing platforms) Smart resume printing: the printer will auto-pause when the filament runs out or breaks, and you can resume printing after a power outage.

- 【More Stable Printing】The Z-axis with dual synchronized lead screws and dual-motor drive for more stable movement of the print head and higher printing accuracy, avoiding the printing deviation driven by a single Z-axis lead screw motor. The 4-wheel V-guide rail pulley is made of POM with more stable movement, low noise, wear resistance, and longer service life.

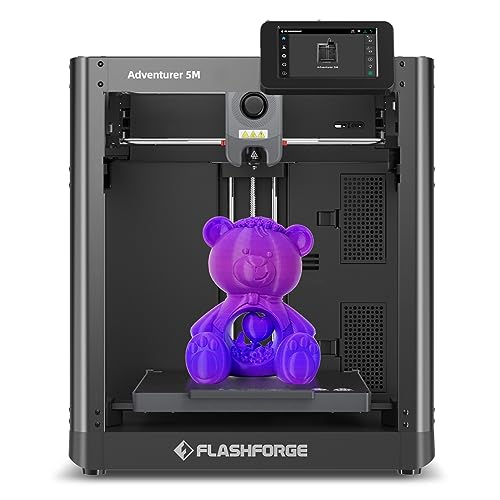

- ✅ 【One-Click Automatic Printing】 -Experience the future of 3D printing with the Adventurer 5M Series. Ensure impeccable bed leveling every time you print, without the need for manual adjustments. Effortlessly achieve consistent adhesion and flawless first layers, saving time and eliminating frustration.

- ✅ 【Swift and Smart Printing 】 -This printer excels in efficiency and intelligence. Its Core XY structure enables travel speeds of up to 600mm/s, ensuring rapid yet accurate printing. It also supports the use of a mobile app-Flash Maker, allowing for remote real-time monitoring of print progress, adjustment of parameters, receiving message alerts, and other functionalities. These features enable intelligent operation, ensuring seamless and uninterrupted printing.

- ✅ 【Your Smart Choice】 -Offers rapid nozzle changes in 3 seconds, a high-flow 32mm³/s nozzle for stable high-speed printing With a quick 35-second warm-up to 200°C, dual-sided PEI platform for easy removal, and multiple platform options, it's a smart and efficient choice for creative projects.

- ✅ 【Superior Print Quality and Adaptability】 -Dual-fan nozzles, vibration compensation, multiple nozzle sizes (0.25, 0.4, 0.6, 0.8mm), and a 280°C direct extruder cater to various materials. From intricate details to rapid prototypes, superior results are guaranteed.

- ✅ 【Efficient After-sales Support】 -All of our 3d printers provide one month free return and exchange. Lifetime technical support, a one-year warranty and reliable 12-hour response service. At FLASHFORGE, zero risk purchase is for every customer's smiles.

Categories of 3D Printers

Before diving into specific models, it’s important to understand the different types of 3D printers, as this will help contextualize the recommendations:

- Fused Deposition Modeling (FDM): The most common and affordable type of 3D printer, which works by melting and extruding thermoplastic filament to build objects layer by layer.

- Stereolithography (SLA): Uses a laser to cure liquid resin into hardened plastic, offering higher precision and smoother finishes than FDM.

- Digital Light Processing (DLP): Similar to SLA but uses a digital light projector screen to flash each layer of the design all at once, making it faster.

- Selective Laser Sintering (SLS): Uses a laser to sinter powdered material, typically nylon, into solid objects. It’s ideal for producing durable parts.

- Multi-Jet Fusion (MJF): Developed by HP, it uses a detailing agent and a fusing agent along with powder to create detailed and robust parts.

What is a 3D printer and how does it work?

A 3D printer is a device that creates three-dimensional objects by building them up layer by layer from a digital model. It works by extruding or solidifying material, such as plastic, resin, or metal, according to the design specifications provided by the user. The process involves slicing the digital model into thin horizontal layers, which the printer then constructs sequentially to form the final object.

What are the main types of 3D printing technologies?

The main types of 3D printing technologies include Fused Deposition Modeling (FDM), Stereolithography (SLA), Digital Light Processing (DLP), Selective Laser Sintering (SLS), and Multi-Jet Fusion (MJF). Each technology differs in the way it deposits or solidifies material, offering various advantages in terms of precision, material compatibility, and application.

What materials can be used in 3D printing?

3D printing materials vary widely depending on the technology used. Common materials include thermoplastics like PLA, ABS, and PETG for FDM printers; UV-curable resins for SLA and DLP printers; and powdered metals or polymers for SLS and MJF printers. Some advanced printers can also work with composite materials, ceramics, and even biocompatible substances.

What are the benefits of 3D printing?

3D printing offers several benefits, including rapid prototyping, customization, and the ability to create complex geometries that are difficult or impossible to produce with traditional manufacturing methods. It also reduces material waste, allows for on-demand production, and can significantly shorten the product development cycle.

What are the limitations of 3D printing?

Despite its many advantages, 3D printing has limitations such as slower production speeds for large quantities, limited material properties compared to traditional manufacturing, and higher costs for certain high-end materials and printers. Additionally, the surface finish and strength of 3D printed parts may not always match those produced by conventional methods.

How do I choose the right 3D printer for my needs?

Choosing the right 3D printer depends on factors like your budget, the materials you want to use, the level of detail and accuracy required, and the intended application. Beginners might prefer an affordable and easy-to-use FDM printer, while professionals might need a high-precision SLA or SLS printer for more demanding tasks.

How much does a 3D printer cost?

The cost of a 3D printer can range from under $200 for basic hobbyist models to several thousand dollars for advanced professional machines. High-end industrial 3D printers can cost tens of thousands or even hundreds of thousands of dollars, depending on their capabilities and the materials they use.

What is the difference between FDM and SLA 3D printing?

FDM (Fused Deposition Modeling) 3D printing works by melting and extruding thermoplastic filament to build objects layer by layer. It is known for its affordability and ease of use. SLA (Stereolithography) 3D printing, on the other hand, uses a laser to cure liquid resin into solid plastic, offering higher precision and smoother surface finishes but typically at a higher cost and with more post-processing requirements.

Can 3D printers print metal objects?

Yes, 3D printers can print metal objects using technologies like Selective Laser Sintering (SLS), Direct Metal Laser Sintering (DMLS), and Electron Beam Melting (EBM). These methods involve sintering or melting metal powder to create solid metal parts, which are commonly used in aerospace, automotive, and medical industries for high-performance applications.

How accurate are 3D printed parts?

The accuracy of 3D printed parts depends on the printer type, the quality of the machine, and the material used. High-end SLA and DLP printers can achieve layer resolutions as fine as 25 microns, while FDM printers typically offer resolutions between 50 and 300 microns. The overall accuracy also depends on factors like calibration, print settings, and post-processing.

What software is used for 3D printing?

3D printing requires software for designing the 3D model (CAD software), slicing the model into printable layers (slicing software), and controlling the printer. Popular CAD software includes AutoCAD, SolidWorks, and Fusion 360. Common slicing software includes Cura, PrusaSlicer, and Simplify3D. Many printers come with their own proprietary software as well.

What is the build volume of a 3D printer?

The build volume of a 3D printer refers to the maximum size of an object that the printer can produce, defined by the dimensions of the printer’s build area. It is usually specified in terms of width, depth, and height (e.g., 220 x 220 x 250 mm). Larger build volumes allow for the creation of bigger parts or multiple smaller parts in a single print run.

What is infill and how does it affect 3D prints?

Infill refers to the internal structure of a 3D printed object, typically composed of a pattern of material within the outer shell. The infill percentage and pattern affect the strength, weight, and print time of the object. Higher infill percentages increase strength and weight but also increase material usage and print time. Common infill patterns include grid, honeycomb, and gyroid.

What are support structures in 3D printing?

Support structures are temporary scaffolds printed alongside the main object to support overhanging features or complex geometries during the printing process. These structures are removed after the print is completed. Different 3D printing technologies use different methods for support, such as breakaway supports in FDM printing or dissolvable supports in SLA printing.

How can I improve the surface finish of my 3D prints?

Improving the surface finish of 3D prints can be achieved through various post-processing techniques. For FDM prints, sanding, smoothing with solvents like acetone (for ABS), or using a surface primer can enhance the finish. For resin prints, additional curing, sanding, and painting can improve the appearance. Ensuring optimal print settings and using finer layer resolutions can also help.

What is the difference between open-source and closed-source 3D printers?

Open-source 3D printers have publicly available designs and firmware, allowing users to modify, upgrade, and customize their machines. They often benefit from community support and a wide range of compatible accessories. Closed-source printers, on the other hand, come with proprietary designs and software, which may limit customization but often provide a more user-friendly and reliable experience.

Can 3D printers create functional parts?

Yes, 3D printers can create functional parts that are used in various industries. Depending on the material and printing technology, these parts can range from simple components to complex mechanical assemblies. Functional parts are commonly produced using strong and durable materials like nylon, polycarbonate, and metal alloys, often employing advanced printing technologies like SLS or DMLS.

What are some common issues with 3D printing and how can they be fixed?

Common issues with 3D printing include warping, stringing, layer shifting, and poor adhesion. These problems can often be fixed by adjusting print settings, ensuring proper bed leveling, using the right print temperature, and maintaining a clean and stable printing environment. Regular calibration and maintenance of the printer also help prevent issues.

How does 3D printing impact the environment?

3D printing can have both positive and negative environmental impacts. On the positive side, it reduces material waste compared to traditional subtractive manufacturing and enables local production, reducing transportation emissions. However, the production and disposal of plastic filaments and resins can contribute to environmental pollution. Recycling programs and the development of biodegradable materials are helping mitigate these concerns.

What is multi-material 3D printing?

Multi-material 3D printing involves using two or more different materials in a single print job. This can be achieved with printers that have multiple extruders or specialized technologies that allow for material mixing. Multi-material printing enables the creation of complex parts with varying properties, such as flexible and rigid sections, or multi-colored objects, expanding the range of possible applications.

Best 3D Printers for Hobbyists and Beginners

1. Creality Ender 3 V2

Overview: The Creality Ender 3 V2 is one of the most popular FDM 3D printers for beginners due to its affordability, reliability, and ease of use.

Key Features:

- Build Volume: 220 x 220 x 250 mm

- Layer Resolution: 0.1-0.4 mm

- Filament Compatibility: PLA, ABS, TPU, PETG

- Price: Around $250

Pros:

- Affordable and accessible for beginners

- Open-source firmware, allowing for modifications and upgrades

- Good print quality for the price

- Quiet operation due to silent stepper motor drivers

Cons:

- Requires manual bed leveling, which can be challenging for beginners

- Assembly is required, although it’s relatively straightforward

Why It’s the Best: The Ender 3 V2 offers a great balance between cost and functionality, making it an excellent entry point for newcomers to 3D printing. Its robust community support and abundance of online resources make troubleshooting and learning easier.

2. Anycubic Photon Mono X

Overview: The Anycubic Photon Mono X is a standout in the SLA category for hobbyists, providing high-resolution prints at a reasonable price.

Key Features:

- Build Volume: 192 x 120 x 245 mm

- Layer Resolution: 0.01-0.15 mm

- Filament Compatibility: 405nm UV resin

- Price: Around $500

Pros:

- High print resolution and detail

- Larger build volume compared to other resin printers in its class

- Fast printing speed due to monochrome LCD

- User-friendly touchscreen interface

Cons:

- Resin printing can be messy and requires post-processing (cleaning and curing)

- Slightly more expensive than entry-level FDM printers

Why It’s the Best: For hobbyists looking to produce detailed models, particularly for miniature figures or highly detailed prototypes, the Photon Mono X offers exceptional quality and speed. Its ease of use and relatively large build volume for a resin printer add to its appeal.

3. Prusa i3 MK3S+

Overview: Prusa Research‘s i3 MK3S+ is known for its reliability, print quality, and community support, making it a favorite among both beginners and experienced hobbyists.

Key Features:

- Build Volume: 250 x 210 x 210 mm

- Layer Resolution: 0.05-0.35 mm

- Filament Compatibility: PLA, ABS, PETG, ASA, Flex

- Price: Around $750

Pros:

- Exceptional print quality and reliability

- Automatic bed leveling

- Extensive community support and active forums

- Robust safety features

Cons:

- Higher price point compared to other beginner printers

- Assembly required, though instructions are comprehensive

Why It’s the Best: The Prusa i3 MK3S+ combines high-quality components, excellent support, and user-friendly features. Its ability to handle a variety of filaments and its robust build quality make it a long-term investment for hobbyists who want to advance their 3D printing skills.

Best 3D Printers for Professionals

1. Ultimaker S5

Overview: The Ultimaker S5 is a top-tier FDM printer designed for professionals who require reliability, large build volumes, and excellent print quality.

Key Features:

- Build Volume: 330 x 240 x 300 mm

- Layer Resolution: 0.02-0.6 mm

- Filament Compatibility: PLA, ABS, Nylon, CPE, PC, PVA

- Price: Around $6,000

Pros:

- Dual extrusion capabilities for multi-material and multi-color prints

- Large build volume suitable for industrial applications

- High precision and consistent print quality

- Easy integration with CAD software

Cons:

- High cost, making it less accessible for small businesses or individual users

- Requires significant space due to its size

Why It’s the Best: The Ultimaker S5 is ideal for professional environments where reliability and print quality are critical. Its dual extrusion system and compatibility with a wide range of materials make it versatile for various applications, from prototypes to functional parts.

2. Formlabs Form 3

Overview: Formlabs Form 3 is a professional SLA printer known for its high resolution and ability to produce finely detailed parts, suitable for dental, jewelry, and engineering applications.

Key Features:

- Build Volume: 145 x 145 x 185 mm

- Layer Resolution: 0.025-0.3 mm

- Material Compatibility: Standard Resins, Tough Resins, Flexible Resins, etc.

- Price: Around $3,500

Pros:

- Exceptional detail and surface finish

- Wide range of proprietary resins for different applications

- Automatic resin dispensing and easy-to-use software

- Reliable and consistent performance

Cons:

- Higher ongoing cost due to resin and consumables

- Smaller build volume compared to some FDM printers

Why It’s the Best: The Form 3’s advanced SLA technology delivers unparalleled precision and surface finish, making it perfect for applications requiring high detail. Its robust ecosystem of resins and ease of use make it a go-to for professionals in various fields.

3. Markforged Mark Two

Overview: The Markforged Mark Two is an industrial-grade FDM printer designed for creating strong, functional parts using composite materials.

Key Features:

- Build Volume: 320 x 132 x 154 mm

- Layer Resolution: 0.1 mm

- Material Compatibility: Onyx, Fiberglass, Carbon Fiber, Kevlar

- Price: Around $13,500

Pros:

- Prints with continuous carbon fiber for extremely strong parts

- High strength-to-weight ratio

- Easy-to-use Eiger software for preparing prints

- Reliable and consistent results

Cons:

- Very high price point

- Smaller build volume compared to other industrial printers

Why It’s the Best: The Mark Two is unique in its ability to print with continuous carbon fiber, making it ideal for manufacturing strong, lightweight, and functional parts. This makes it an excellent choice for industries like aerospace, automotive, and product development.

Top 3D Printers for Specific Applications

1. Raise3D Pro2 Plus – Best for Large-Format Printing

Overview: The Raise3D Pro2 Plus offers an extensive build volume, making it suitable for large-scale projects and industrial applications.

Key Features:

- Build Volume: 305 x 305 x 605 mm

- Layer Resolution: 0.01-0.25 mm

- Filament Compatibility: PLA, ABS, PETG, TPU, HIPS, Nylon

- Price: Around $6,000

Pros:

- Very large build volume

- Dual extrusion for complex prints

- Enclosed build chamber for temperature stability

- Robust build and high-quality components

Cons:

- Expensive and large footprint

- Complex setup and calibration

Why It’s the Best: For projects requiring large parts, the Raise3D Pro2 Plus is unparalleled. Its dual extrusion system and enclosed build chamber provide the flexibility and stability needed for high-quality, large-scale prints.

2. Peopoly Phenom L – Best for Large Resin Prints

Overview: The Peopoly Phenom L is a large-format SLA printer that offers the ability to create detailed resin prints on a much larger scale than typical resin printers.

Key Features:

- Build Volume: 345 x 194 x 400 mm

- Layer Resolution: 0.05-0.1 mm

- Material Compatibility: 405nm UV resin

- Price: Around $2,000

Pros:

- Large build volume for resin prints

- High detail and precision

- Faster print speeds due to monochrome LCD

- Affordable for its size and capabilities

Cons:

- Resin handling and post-processing are more demanding

- Requires regular maintenance and calibration

Why It’s the Best: For applications needing large and detailed resin prints, such as in medical modeling or custom art, the Phenom L offers a unique combination of size and detail. Its affordability for the given build volume makes it a standout option.

3. LulzBot TAZ Pro – Best for Multi-Material Printing

Overview: The LulzBot TAZ Pro is a versatile FDM printer capable of handling multiple materials and colors, making it ideal for complex and functional prints.

Key Features:

- Build Volume: 280 x 280 x 285 mm

- Layer Resolution: 0.05-0.4 mm

- Filament Compatibility: PLA, ABS, PETG, TPU, Nylon, Polycarbonate

- Price: Around $4,950

Pros:

- Dual extrusion for multi-material and multi-color prints

- Large build volume

- Open-source and modifiable

- Reliable and consistent print quality

Cons:

- Higher cost

- Complex setup and calibration for dual extrusion

Why It’s the Best: The TAZ Pro’s ability to handle different materials and colors simultaneously makes it a powerful tool for creating functional prototypes and complex parts. Its large build volume and open-source nature provide additional flexibility for advanced users.

Conclusion

The best 3D printer for you will depend on your specific needs, budget, and level of expertise. For beginners and hobbyists, the Creality Ender 3 V2, Anycubic Photon Mono X, and Prusa i3 MK3S+ offer excellent entry points into the world of 3D printing. For professionals, the Ultimaker S5, Formlabs Form 3, and Markforged Mark Two provide the precision, reliability, and material capabilities needed for demanding applications. Additionally, for specialized tasks, the Raise3D Pro2 Plus, Peopoly Phenom L, and LulzBot TAZ Pro stand out for their unique strengths.

As 3D printing technology continues to evolve, the range of available printers will only expand, offering more options tailored to specific needs and applications. Whether you’re looking to prototype a new product, create intricate models, or produce functional parts, there’s a 3D printer out there that can help you achieve your goals.